Electricity generation from heat

Heat can be converted into electricity in a variety of different ways that produce zero additional emissions and require zero additional fuel. The power that is produced is often base-load (continuously producing) and typically requires minimal maintenance. Sound too good to be true? It isn't.

Benefits

The primary benefit of turning heat into electricity is the sale (or reduced consumption) of electricity from the heat producer's site. But there are additional potential benefits, including:

Revenues from the sale of electricity (or avoided electricity costs)

Base-load power production

Environmental benefits from the creation of emission free electricity

Reduction in system parasitic losses

Potential hedging of energy costs

Read more about it in our Economics section

How it's done

Heat can be converted into electricity in a variety of different ways. Some technologies are solid state, some use turbines, others use pistons and have different working fluids. Of all the different technologies available, the heat to power conversion process falls into three primary categories.

1) Rankine Cycle Generators

These 'traditional' generators operate using a 'working fluid', which could be gas, liquid, or both depending on the cycle. The general steps in the Rankine Cycle are described below:

Compress - A pump compresses the working fluid, increasing its pressure.

Heat In - Heat is applied from the waste heat source to further increase the pressure of the working fluid. In some applications this includes a phase change from liquid to vapor.

Expand - Here we can extract work by expanding the hot, pressurized working fluid to cool it down and reduce the pressure. This is usually done with a spinning turbine.

Cooling - To create a pressure differential (which drives the expansion step) the pressure must be reduced on the back end of the expansion. Removing heat will reduce the pressure and could involve a phase change back into liquid from gas. Heat removal is often accomplished with an air radiator or water cooling tower.

The primary technologies that use the Rankine Cycle are listed below.

The Rankine Cycle, by which heat is converted into electricity in a closed loop with an expander + generator. The Organic Rankine Cycle follows the same schematic but with a different working fluid in place of water.

Steam Cycle

Steam systems have been around for hundreds of years and have been used in countless applications due to their relatively efficient operation. Historically, steam turbines had been found mostly in large (100+ MW), high temperature (400C +), utility scale plants. Typical applications would be in combination with gas turbines in a combined cycle plant or nuclear power stations.

More recently, smaller and lower temperature microturbines have been developed that open the market down to around 200C and 1 MW. Though the lower temperature does reduce the potential efficiency (See the Carnot Efficiency section), in some applications, these microturbines can be effective.

Organic Rankine Cycle (ORC)

ORC's operate under the same fundamental principles as the Steam Cycle, but use an 'organic' medium instead of water as the working fluid in the process. The organic fluid is typically a refrigerant that has a lower boiling point than water, which enables access to lower temperature heat sources compared to steam turbines.

ORC's benefit from lower operating pressures, and accessing lower temperature heat sources but they typically do not match the efficiency of steam generators. Modern ORC's were developed in the 1960's and are commonly used today in geothermal applications.

Kalina Cycle

The Kalina cycle is a variation of the Rankine cycle that uses a mixture of two materials as the working fluid. Using two different liquids allows the mixture to boil at different temperatures, providing efficient use of available heat. By tuning the mixture ratio, a Kalina system can be customized for a specific heat source temperature.

While this technology is not as pervasive as others, there are several multi-MW installations that have proven out the design. The potential increase in thermal efficiency over other technologies makes it an attractive option to consider.

2) Stirling Engines

Though the Stirling cycle has been around for nearly 200 years, commercial Stirling engines have only recently become available. The Stirling cycle is similar to the Rankine cycle except that there is no phase change or mechanical compression of the fluid. The main steps of the Stirling cycle are:

Expansion - Heat is applied from the waste heat source to expand the working fluid and produce power

Heat removal - A displacer forces the working fluid past a recuperator, which removes heat from the fluid and stores it by heating up a material

Compress - The working fluid is cooled externally by air, water or some other coolant, increasing its density

Heat recuperation - The displacer forces the cool working fluid back across the recuperator, where it picks up the stored heat

Animated Engines has some great diagrams explaining the Stirling cycle in more detail.

3) Thermoelectric generators

Thermoelectric generators are solid state devices that convert heat directly into electricity, so there are no rotating or reciprocating components. In a nutshell, thermoelectrics create electric current from a temperature gradient or differential.

One side of the thermoelectric is exposed to the waste heat source while the other side is cooled with air, water, or some other coolant. Inside, there are two materials, one that makes electrons flow toward the hot end and one that makes electrons flow away from the hot end. As heat is applied, the two materials produce a voltage differential, which produces an electric current that we use as power.

Thermoelectrics are generally less efficient and more expensive than rotating machinery generators, however the fact that they do not have any moving parts can enable simpler installation and operation. Like solar panels in many ways, they can scale to operate at an industrial scale, but also be used in small, consumer devices.

Other technologies

Supercritical CO2 Cycle: The supercritical carbon dioxide power cycle operates in a manner similar to other turbine cycles, but it uses CO2 as the working fluid in the turbomachinery. The cycle is operated above the critical point of CO2 so that it does not change phases (from liquid to gas), but rather undergoes drastic density changes over small ranges of temperature and pressure. This allows a large amount of energy to be extracted at high temperature from equipment that is relatively small in size. (source: NETL)

While the sCO2 cycle is exciting due its potential to drastically reduce the size of generating equipment, the technology is not commercially available. Several organizations are working to bring a product to market, but at this point they are still in development.

Additional information on these technologies and others can be found in this US EPA waste heat to power technology assessment paper: Waste Heat to Power Systems - a technology overview done by the CHP Partnership & US EPA.

Different technologies for different temperatures

In general, higher temperature heat sources can be converted more efficiently into electricity than lower temperature heat sources. This phenomenon is described by Carnot's Theorem, which places an upper limit on the efficiency that a heat engine can obtain.

Maximum efficiency = n = 1 - (Tc/Th)

Tc = the cold side temperature

Th = the hot side temperature

So the higher the temperature difference between the hot side and cold side of a heat engine, the higher potential efficiency. The specific method and equipment of a particular application will dictate how far below the ideal efficiency a real application operates.

Major components of a heat to power project

1. Heat recovery

Before heat can be converted into electricity, it must be captured or extracted from the heat source. This can be done in a variety of ways, but often involves a heat exchanger or heat recovery boiler. Both transfer heat from the primary fluid to a secondary one. Some applications can make direct use of a heat source, but in practice, most waste heat recovery installations will have an intermediate loop. See more on the Heat recovery page.

2. Heat transfer

Once the heat is captured, it must be transferred to the component that converts it into electricity. In some cases, a medium or power conversion fluid can be directly used with an exhaust stream. In other cases, an intermediate loop is used to transfer the heat energy to a heat-to-power generator. The advantage of a direct system is the reduction in parasitic losses (pump parasitics and heat transfer losses) associated with an intermediary loop. However, an intermediary loop can cover long distances and regulate the temperature that is received by the heat-to-power generator. Many high temperature heat-to-power generators use 'direct evaporation' methods with no intermediary loops. For any site, it is best to analyze the heat source and quote multiple suppliers to see which technology can achieve the greatest net output, weighed against the costs of the system.

3. Heat-to-power conversion

Once the heat has been captured and transferred to the generator, there are a multitude of ways to convert it into electricity. The best way to think about this stage is to analyze different options and vendors that are available, understand the output they can achieve compared to the cost of installation and operation, and make a decision. Refer back to our technologies section about the benefits of each technology, and our calculator. Some technologies are about maximizing electricity output, others are about reliability, some are a mix.

4. Heat rejection

The last component of any heat to power conversion process is heat rejection, or condensing. In lower temperature cycles, lower cooling temperatures are critical in order to get a higher temperature delta (see Carnot Theorem). And in higher temperature cycles, there may be a heat utilization option that will work with higher condensing temperatures . The most common cooling fluids are ambient air and water. Air can be used with a radiator, which uses fans to blow ambient air over finned tubes to cool the working fluid. If cool water is available (e.g. near the ocean) then it can be used to cool the working fluid directly. Cool water can be produced using a cooling tower, which cools the water by evaporation. Each application must be evaluated based on the condensing load, temperature, and ambient temperature swings throughout the year.

5. Integration and interconnection

The power that is produced through the heat-to-power conversion process must be connected to grid or used on site. In some cases, this may require transformers, disconnect switches, inverters, power electronics, etc. In addition to the power connection, often units are connected to a remote monitoring system and/or SCADA system for additional visibility on performance.

Key considerations

Efficiency isn't everything

Most power generators focus on efficiency. With heat-to-power generators, efficiency means very little. Why? In traditional power generation, efficiency is a measure of how effectively a technology converts a finite amount of fuel into something productive. With waste heat utilization, the fuel is free and some technologies can use or 'access' more of it. To be specific, the lower temperature (and therefore lower efficiency) cycles can access more heat from a given source than the higher temperature (and therefore higher efficiency) cycles. As a result, a lower efficiency heat to power generator can sometimes get more power out of a heat source than can a higher efficiency generator. As a result, it is recommended to analyze each heat source individually and compare the options for generating electricity across the different technologies.

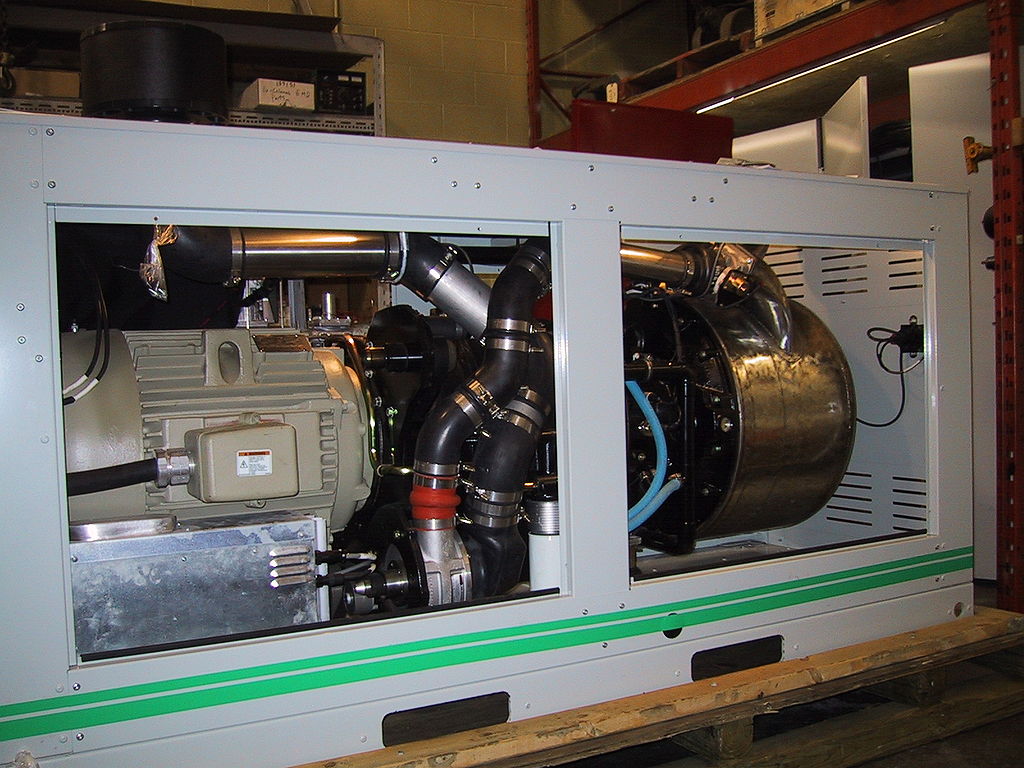

When comparing costs, make sure the whole scope is included

Many heat to power generators are 'skids' or skid mounted units that include the prime mover equipment to create power. However, as noted in the section above, there are a number of components that must be included for the whole heat to power project to work.

Get the estimated "net output" from the whole site when calculating economics

Like the costs, arriving at the true net power of a project requires taking a holistic view of the installation. Net power means the electricity that can be exported for use, after subtracting all parasitic losses (pumps, condenser fans, blowers, electronics, etc.). This is especially critical on heat to power projects because parasitic losses can make up proportionally much more of a total project than with other fuel based power generator system.

Check out our Calculator to see how much heat you have available and what you can do with it.

Links to additional information

Waste Heat to Power Market Assessment - Prepared for Oakridge National Laboratory

Heat is Power Association - A US based non-profit promoting heat to power

Waste Heat to Power Systems - a technology overview done by the CHP Partnership & US EPA.

Waste Heat Recovery: Technologies and Opportunities in US Industry - US DOE